Key Takeaways

- A solenoid coil is an electrical coil made of tightly wound copper wire that creates a magnetic field to move parts in auto systems like starters, transmission valves, and fuel systems

- When current flows through the coil, it pulls a plunger or opens and closes a valve to perform mehcanical work in the vehicle

- A bad solenoid coil can cause hard starting, shifting issues, stalling, warning lights, or intermittent electrical faults that leave you stranded

- Basic testing can be done with a multimeter by checking resistance and continuity, and by verifying proper voltage supply at the coil terminals

- Replacing damaged or burnt coils quickly helps prevent bigger failures in starters, transmissions, or fuel and hydraulic systems

What Is A Solenoid Coil in Auto Parts?

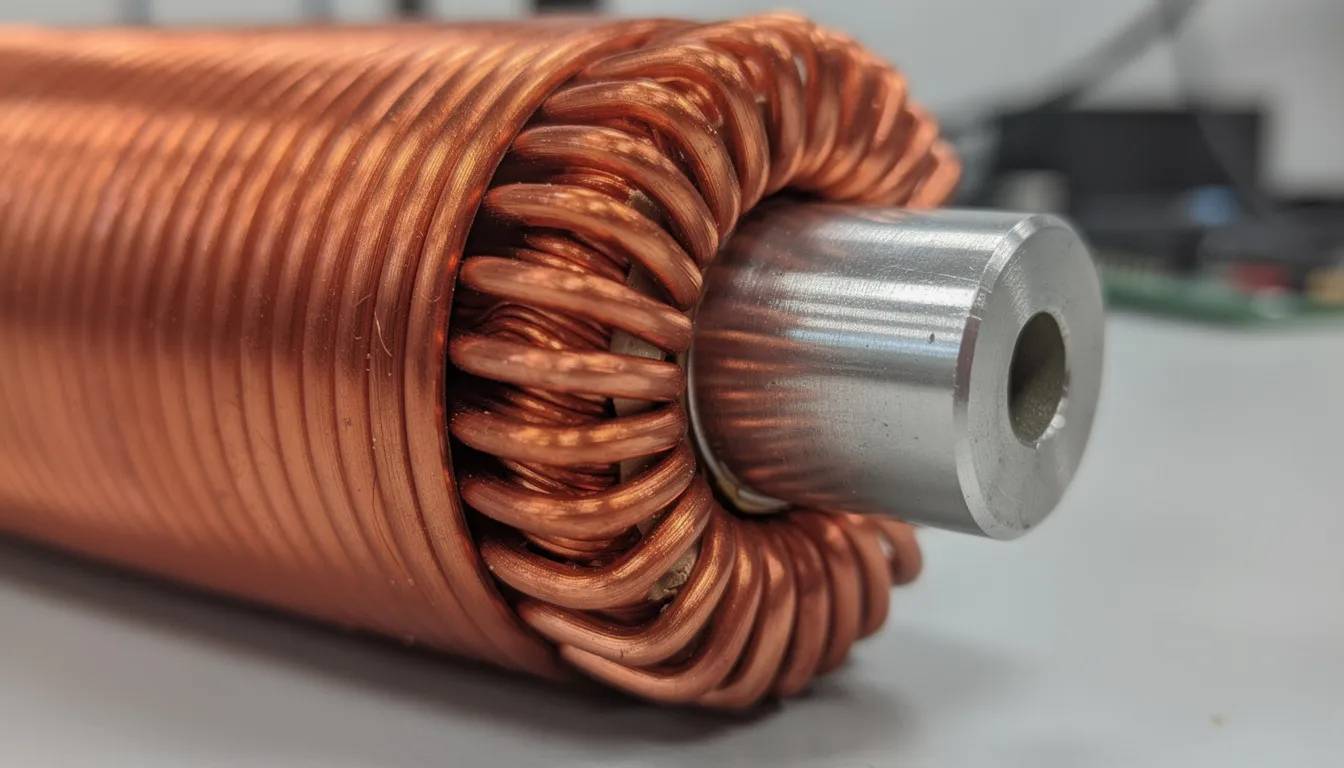

A solenoid coil is a tightly wound copper wire component that turns electrical energy from your vehicle’s battery into magnetic force. Think of it as the heart of an electromagnet. When power flows through those windings, the coil generates a strong magnetic field that can move metal parts with precision and speed.

In automotive systems, the solenoid coil is usually part of a larger solenoid assembly. This assembly typically includes a housing, a movable plunger or armature, a return spring, and sometimes valve components. The coil itself does not move. Instead, it creates the magnetism that moves everything else around it.

You will find solenoid coils in many places across your car, truck, or heavy equipment:

- Starter solenoid coil -- Mounted on or near the starter motor, it engages the starter drive with the engine flywheel

- Transmission shift solenoid coils -- Located inside automatic gearboxes to control hyraulic fluid flow and gear changes

- Fuel shutoff solenoid coils -- Found on diesel engines to cut fuel supply when you turn off the ignition

- Hydraulic control solenoid coils -- Used in heavy equipment like loaders and excavators to direct hydraulic fluid

At Fab Heavy Parts, the focus is on robust, heavy-duty solenoid coils designed for trucks, construction machines, agricultural equipment, and other commercial vehicles.

How Does A Solenoid Coil Work in A Vehicle?

The working principle is simple but effective. Current flows through the coil, a magnetic field forms inside it, and that field pulls or pushes a metal plunger or armature. The number of turns in the coil, the amount of current, and the core material all determine how strong the pull will be.

Here is what happens step-by-step when you turn the key or press the start button in your car:

- The battery sends current through the ignition switch to the starter solenoid coil

- The coil energizes and creates a strong magnetic field around its iron core

- This field pulls the metal plunger inside the solenoid toward the core

- As the plunger moves, it closes a set of heavy-duty electrical contacts

- Those contacts connect the battery directly to the starter motor

- The starter motor spins and engages the engine’s flywheel to crank the engine

The magnetic field strength depends on a straightforward formula. In simple terms, more turns in the coil and higher current means a stronger field. The iron or steel core inside the winding amplifies this effect, concentrating the field lines into a powerful force.

When you release the key, the current stops flowing. The magnetic field collapses almost instantly. The return spring then pushes the plunger back to its resting position, the contacts open, and the starter disengages. This all happens in a fraction of a second.

The same basic principle applies whether you are looking at a long solenoid in a transmission valve body or a compact unit in an emissions system. The direction of plunger movement and the size of the device may differ, but the underlying magnetism is identical.

Main Automotive Uses of Solenoid Coils

Solenoid coils show up anywhere a vehicle needs electrical control over mechanical movement or fluid flow. They are the bridge between your car’s electronic brain and its physical actions.

Starter Solenoid Coils

These are probably the most familiar type. The starter solenoid coil connects the battery to the starter motor when you command an engine start. In most applications, this solenoid is installed directly on the starter housing or mounted nearby on the fender or firewall.

When energized, the coil does two jobs at once:

- It pushes the starter drive gear into mesh with the flywheel ring gear

- It closes the main contacts to send high current to the motor

This design keeps the high-amperage circuit separate from your ignition switch, which only handles the low current needed to activate the coil.

Automatic Transmission Solenoid Coils

Modern automatic gearboxes rely heavily on solenoid coils. These components open and close hydraulic passages inside the valve body to control gear shifts, torque converter lockup, and line pressure. A typical 6-speed or 8-speed automatic may have six or more individual shift solenoids.

Electronic control modules send signals to these coils in precise patterns. Some operate as simple on-off valves. Others use pulse-width modulation to vary the flow, allowing smooth, nearly seamless gear changes. When one of these coils fails, you often end up in limp mode with harsh or delayed shifts.

Fuel System Solenoid Coils

Diesel engines commonly use fuel shutoff solenoid coils to cut fuel flow when you turn off the ignition. Without this device, a diesel would keep running as long as fuel reached the injection pump. The solenoid acts as a positive shutoff.

On gasoline engines, you will find solenoid coils in evaporative emission (EVAP) purge valves. These control fuel vapors from the tank, directing them to the engine for burning instead of releasing them to the atmosphere.

Heavy-Duty and Specialty Applications

Beyond the typical car or light truck, solenoid coils serve critical roles in:

|

Application |

Function |

|

Hydraulic valve solenoids |

Direct oil flow in loaders, excavators, and forklifts |

|

ABS and traction control |

Modulate brake pressure during wheel slip events |

|

EGR solenoids |

Control exhaust gas recirculation for emissions |

|

Power steering |

Assist with hydraulic pressure in some systems |

These applications demand great durability. A hydraulic solenoid on a backhoe may cycle thousands of times in a single day of work.

How to Test An Automotive Solenoid Coil

Before you start any electrical testing, take basic safety precautions. Disconnect the battery ground cable when required. Follow your vehicle’s service guidelines. Avoid testing on hot engine components where burns or accidental shorts could occur.

Resistance (Ohms) Test

This is the most common check for a solenoid coil. You will need a digital multimeter set to the ohms function.

- Disconnect the electrical connector from the solenoid

- Place your multimeter leads on the two coil terminals

- Read the resistance value displayed

For automotive solenoids, typical resistance ranges fall between:

- Starter solenoids: 3–20 ohms

- Transmission shift solenoids: 10–30 ohms

- Fuel shutoff solenoids: 5-25 ohms

An open circuit reading (infinite resistance or “OL”) means the coil winding is broken. Very low resistance (less than 1 ohm) suggests shorted turns inside the winding. Either condition means the coil has failed.

Continuity and Ground Short Test

After checking resistance, verify there is no short to ground. This is important on coils designed with isolated windings.

- Measure resistance between each coil terminal and the metal housing

- The reading should exceed 100 kilohms (often showing as open)

- If you see low resistance, the insulation has broken down and the coil is grounded

Voltage Supply Test

Sometimes the coil is fine but is not receiving power. With the ignition on or during a start command, check for proper voltage at the coil connector.

- Use your multimeter on DC voltage

- One lead goes to battery ground, the other to the power wire

- You should see close to battery voltage (12–14V) when the circuit is commanded on

Low or missing voltage points to wiring problems, blown fuses, or control module issues rather than a bad coil.

Functional Bench Test

For a quick function check, you can apply 12 volts directly to the solenoid terminals and listen for a solid click as the plunger moves. If voltage and resistance readings look good but you hear no click or movement, the problem is likely mechanical—a stuck plunger or internal damage.

Common Symptoms of A Bad Solenoid Coil

Solenoid coil failures can be partial or complete. Sometimes they work fine when cold but fail after the engine warms up. Other times they quit suddenly with no warning. Learn to recognize the symptoms so you can address problems before they strand you.

Starter-Related Symptoms

When the starter solenoid coil fails, you may experience:

- Turning the key and hearing only a single click, or nothing at all

- Intermittent no-crank conditions that come and go

- The engine cranking only when the vehicle is cool, then refusing to start after a drive

- A grinding noise if the solenoid engages partially but does not fully mesh the drive gear

Transmission-Related Symptoms

A failing transmission solenoid coil often triggers:

- Delayed engagement when shifting from Park to Drive or Reverse

- Harsh, jarring shifts between gears

- Being stuck in one gear (limp mode or fail-safe mode)

- Warning lights on the dashboard and stored trouble codes like P0750 or similar shift solenoid malfunction codes

Industry data suggests that about 70% of solenoid-related transmission codes correlate with high coil resistance—a sign the windings are degrading.

Fuel and Emission Symptoms

Problems with fuel or emission solenoid coils may cause:

- Engine stalling when warm, especially at idle

- Difficulty shutting off a diesel engine (the engine runs on after key is turned off)

- Rough idle when EVAP purge or EGR solenoids fail

- Check engine lights and emissions test failures

Physical Signs

Sometimes you can spot trouble with your eyes and nose:

- Burnt smell near the solenoid location

- Melted or discolored plastic on the connector or housing

- Visible corrosion at terminals and connectors

- Dark, damaged insulation visible through the housing

These physical signs are strong indicators that the solenoid coil or its immediate environment is compromised and needs attention.

Why Solenoid Coils Fail And How to Prevent Damage

Solenoid coils fail from heat, vibration, electrical overload, and contamination. Heavy-duty and off-road environments accelerate these problems. Understanding the causes helps you take steps to extend coil life.

Thermal Stress

Heat is the number one enemy of coil windings. The insulation on the copper wire can only handle so much temperature—typically rated between 105°C and 155°C depending on the material class.

Problems that cause overheating include:

- Extended cranking times when the engine will not start

- High ambient temperatures in the engine bay

- Poor heat dissipation from blocked airflow or mounting position

- Coils stuck in the energized position due to control faults

Electrical Issues

Low system voltage is particularly damaging. When voltage drops, the coil draws more current trying to develop the same magnetic field strength. This extra current produces more heat inside the windings.

Other electrical problems include:

- Incorrect wiring or poor connections causing resistance

- Short circuits in the harness or control module

- Using a coil outside its designed duty cycle (continuous versus intermittent rating)

Mechanical and Environmental Factors

Solenoid coils in vehicles face tough conditions every day:

- Oil or coolant leaks that soak into the windings and degrade insulation

- Water intrusion through damaged connectors or seals

- Road salt causing corrosion on terminals and housings

- Constant vibration loosening internal connections or cracking brittle insulation

Prevention Tips

You can help your solenoid coils last longer with some simple practices:

- Repair leaks quickly – Do not let fluids pool around electrical components

- Avoid unnecessary long cranking – If the engine does not start in 10 seconds, stop and diagnose the problem

- Keep connectors clean and tight – Use dielectric grease on terminals when specified

- Inspect harness routing – Make sure wires are not rubbing on exhaust or moving parts

- Maintain your charging system – A healthy battery and alternator protect all electrical components

Repair or Replace? Handling A Failed Solenoid Coil

In most automotive applications, a failed solenoid coil is replaced as a complete assembly rather than rewound on the vehicle. Rewinding requires specialized equipment and precise specifications that are not practical in a typical shop setting.

Typical Repair Approaches

The replacement strategy depends on the type of solenoid and its location:

|

Solenoid Type |

Common Replacement Approach |

|

Starter solenoid |

Replace entire starter or solenoid assembly |

|

Transmission solenoid |

Replace individual solenoid or full valve body solenoid kit |

|

Fuel shutoff solenoid |

Replace complete solenoid module |

|

Hydraulic solenoid |

Replace valve cartridge assembly |

For transmission solenoids, many technicians recommend replacing the full set of shift solenoids when one fails, especially on high-mileage vehicles. This prevents repeat teardowns and addresses components that may be nearing the end of their service life.

Following Proper Procedures

When replacing a solenoid assembly, follow the vehicle’s service manual for:

- Correct torque specifications on fasteners

- Replacement of gaskets, O-rings, or seals

- Fluid fill and level procedures

- Relearn or adaptation procedures for electronic controls

This is especially important for transmission and engine control solenoids where the control module may need to relearn valve characteristics.

Sourcing Quality Replacement Parts

For heavy-duty trucks, construction machines, and commercial vehicles, sourcing durable replacement solenoid coils is essential. Fab Heavy Parts stocks robust components designed for compatibility with demanding applications. Quality matters when you need a product that will hold up to heat, vibration, and long duty cycles.

Post-Repair Verification

After installation, take time to verify everything works correctly:

- Clear any diagnostic trouble codes stored in the control module

- Operate the system under load to confirm proper function

- Check for leaks around gaskets and seals

- Listen for abnormal noises or vibrations

- Perform a road test or work-cycle test as appropriate for the equipment

These steps ensure the repair is complete and the new component is functioning as designed.

FAQ

Q1: How long does an automotive solenoid coil usually last?

A1: A quality solenoid coil can often last 8 to 15 years or well over 150,000 miles under normal driving conditions. However, heavy towing, extreme temperatures, frequent short trips, and off-road use can shorten that lifespan significantly. Starter solenoid coils tend to fail sooner on vehicles with lots of short trips and frequent restarts. Transmission and fuel solenoid coils often fail with age, fluid contamination, or lack of regular maintenance. In heavy equipment, coils may last fewer years simply due to the high cycle count they experience during daily operations.

Q2: Can a weak battery damage a solenoid coil?

A2: A weak battery itself does not typically burn out a coil, but the secondary effects can cause damage. When battery voltage is low, the solenoid may not fully engage, causing the driver to hold the key in the start position longer. This extended energizing time generates excess heat in the coil windings. Repeated episodes of long cranking with low voltage can eventually break down the insulation and cause premature failure. Keeping your battery charged and your charging system healthy protects both the starter motor and its solenoid coil from excessive stress.

Q3: Is it safe to drive with a failing transmission solenoid coil?

A3: In many cases the vehicle will still move, but you may experience harsh or delayed shifts, or the transmission may operate in a limited limp mode with only one or two gears available. Continuing to drive this way increases wear on clutches, bands, and other internal parts. What starts as a relatively inexpensive solenoid replacement can turn into a major transmission rebuild if ignored. Treat solenoid-related transmission codes and symptoms as urgent. Have the system inspected and repaired before long trips or heavy hauling to avoid costly secondary damage.

Q4: Can solenoid coils be rewound instead of replaced?

A4: While rewinding a solenoid coil is technically possible in a specialized electrical shop, it is rarely practical for automotive parts. Complete new solenoid assemblies are widely available and designed to match original specifications. A properly designed replacement assembly provides correct resistance values, proper fit, and a faster turnaround than custom rewinding. For most vehicle owners and technicians, replacement is the straightforward and reliable choice. Only in rare cases involving obsolete or specialty equipment might rewinding be considered.

Q5: What tools do I need to check a solenoid coil at home?

A5: Basic solenoid coil testing needs only a few tools:

Digital multimeter with resistance and DC voltage functions

Basic hand tools (wrenches, screwdrivers, sockets)

Safety gloves and eye protection

Vehicle wiring diagram or service info

These allow resistance checks, voltage verification, and simple functional tests. If unsure about working with high-current circuits or complex systems, seek a qualified technician. Modern vehicles often need scan tools and expertise for accurate diagnosis. Knowing your limits prevents turning small issues into big problems.

Popular Solenoid Coils at Fab Heavy Parts

1.

New 12V Solenoid Coil 3587119 for Yanmar Engine 4TNV94 4TNV98

Part Number: 3587119

Condition: new, aftermarket

Voltage: 12V

Warranty: one year

2.

12V Solenoid Valve Coil 466-2973 4662973 Fits for Caterpillar CAT Loader 259D Replacement

Part Number: 466-2973, CA4662973, 4662973, CA466-2973

Application: The Solenoid Valve Coil fits for Caterpillar CAT Loader 259D

Condition: new, aftermarket

Specification: Coil Diameter: 18mm; Height: 50mm; Voltage: 12V

3.

12V Solenoid Valve Coil R901394391 OD0236203POB00 OD0236203POB00-36-K40-20G12 02 Fits for Rexroth

Part Number: R901394391, OD0236203POB00, OD0236203POB00-36-K40 -20G12 02, OD0236203POB0036K40 20G12 02

Condition: new, aftermarket

Application: The Solenoid Valve Coil fits for Rexroth

4.

24V Solenoid Valve Coil 280776 280775 Fits for Bucher

Part Number: 280776, 280775

Condition: new, aftermarket

Application: The Solenoid Valve Coil is compatible with Bucher

5.

Solenoid Coil 104761GT 4303212 Fits for Genie GS-3390 GS-4390 GS-2668 SX-180 SX-150

Part No.: 104761GT, 4303212

Application: The Solenoid Coil fits for Genie GS-3390, GS-4390, GS-2668, SX-180, SX-150

Condition: new, aftermarket

6.

36W Solenoid Valve Coil CAE-28DC/10 Fits for Atos

Part Number: CAE-28DC/10, CAE28DC10, CAE 28DC 10

Condition: new, aftermarket

Application: The Solenoid Valve Coil fits for Atos

FAB Heavy Parts Can Help With Your Needs

Welcome to Fab Heavy Parts' online catalog, where you can explore a delightful array of Solenoid Coils. We have a diverse selection to cater to your needs. Our knowledgeable parts team is at your disposal, ready to assist you every step of the way.