If you’ve ever watched an experienced operator swap a bucket for a grapple in under a minute, you’ve witnessed the Bob-Tach system in action. This quick-attach mounting interface has become the backbone of productivity for countless Bobcat skid steer and compact track loader operators worldwide. This guide is intended for Bobcat loader operators, equipment managers, and buyers interested in maximizing loader versatility and maintenance. Whether you’re looking to buy replacement parts, understand how the system works, or find the right attachments for your machine, this guide covers everything you need to know. A well-maintained Bob-Tach system ensures safe, efficient, and versatile operation on any job site.

Key Takeaways

- Bob Tach (often written Bob-Tach) is the quick-attach mounting system used on Bobcat skid-steer and compact track loaders, enabling fast, tool-free attachment changes that can take under one minute to complete.

- The Bob-Tach interface has become an ISO-recognized industry standard, giving operators confidence in secure attachment locking and durability across demanding worksites in construction, landscaping, agriculture, and municipal work.

- Core Bob-Tach components include the mounting plate, upper hooks, lower locking wedges, pivot pins, return springs, and left/right hand control levers—all working together to clamp and release attachments safely.

- Compatibility spans numerous Bobcat models and common attachments including buckets, backhoes, snowplows, trenchers, augers, and grapples, with most Bobcat-branded attachments from the early 2000s onward designed for plug-and-play fit.

- Regular maintenance of lever kits and wear parts keeps your Bob-Tach system tight, safe, and easy to operate over many years, preventing costly downtime and potential security issues on the job site.

What Is a Bob-Tach Mounting System?

The Bob-Tach mounting system enhances the functionality of Bobcat loaders by making it easy to switch out attachments. The Bob-Tach mounting system redefined how compact equipment connects to attachments. Bob-Tach is Bobcat’s proprietary quick-attach system, often informally searched online as “bob tach” or “quick tach.” It represents a mechanical and hydraulic mounting interface positioned at the front of skid-steer and compact track loaders, allowing rapid switching between attachments without requiring tools, mounting kits, or extensive downtime.

The system has earned ISO recognition as a standardized attachment interface, which means customers can purchase attachments with confidence knowing they’ll match their compatible Bobcat loaders. This standardization emerged from Bobcat’s early innovation addressing industry pain points around attachment swapping efficiency—previously, changing tools required labor-intensive bolting or pinning methods.

Typical use cases for Bob-Tach equipped machines include:

- Landscaping: Switching between buckets, landscape rakes, and grapples throughout the day

- Construction: Moving from grading buckets to pallet forks to augers on the same job site

- Agriculture: Alternating between material handling and trenching operations

- Snow removal: Quick transitions between snow blades, blowers, and brooms

- Municipal work: Versatile tool changes for varied public works tasks

How the Bob-Tach System Works

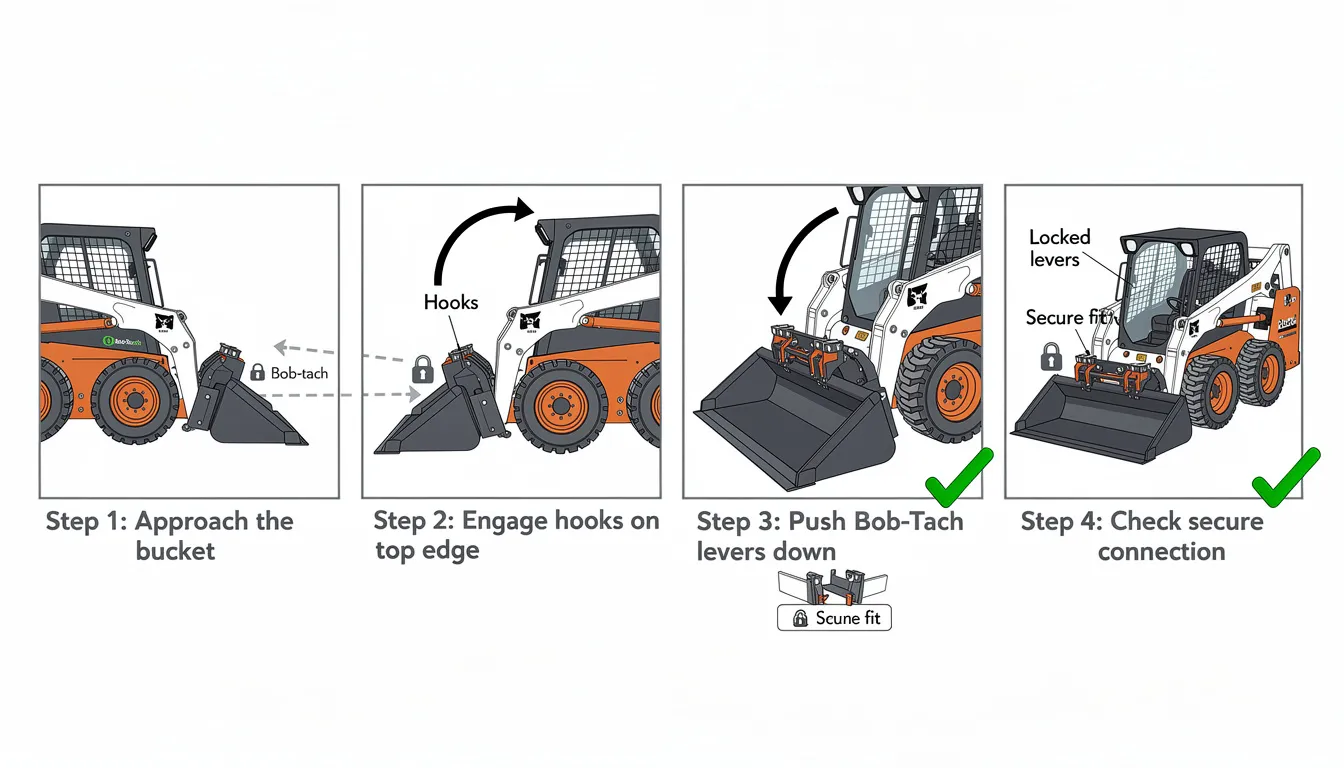

Understanding the step-by-step operation of locking and unlocking attachments helps operators use the system effectively and recognize when something isn’t functioning correctly.

The Mechanical Principle

The Bob-Tach system operates through a straightforward but robust mechanical principle. Upper hooks on the Bob-Tach plate catch the top edge of the attachment plate, while lower locking wedges are driven upward to clamp the bottom edge securely. This dual-point engagement creates a tight-fit connection capable of withstanding high breakout forces during demanding digging and material handling operations.

Manual Lever Operation

For standard Bob-Tach systems, the attachment process follows these steps:

- Approach: Drive the loader toward the attachment with arms at the appropriate height

- Hook: Tilt the Bob-Tach plate forward slightly and engage the upper hooks on the attachment’s top edge

- Seat: Raise the lift arms to fully seat the attachment against the mounting plate

- Lock: Exit the cab and push down both the left and right hand locking levers until they’re fully engaged

- Test: Return to the cab and test the attachment by lifting and curling to verify secure engagement

Power Bob-Tach Option

Bobcat also offers Power Bob-Tach as an optional upgrade on many models. This hydraulic version allows operators to engage the locking wedges from inside the cab using a simple dash panel switch. According to product demonstrations started around 2009, Power Bob-Tach reduces attachment change time to under one minute while eliminating the need to exit the machine—particularly valuable in adverse weather or hazardous conditions.

Verifying Proper Engagement

A properly engaged Bob-Tach connection shows these characteristics:

- Levers fully down (manual) or hydraulic pins fully extended (power)

- Attachment flush against the mounting plate with no visible gap

- No rocking or play when lifting and curling the attachment

- Smooth operation without unusual sounds or resistance

Key Components of a Bob-Tach Mounting System

Understanding each component helps with troubleshooting, maintenance, and ordering the right replacement parts when wear occurs. The Bob-Tach system uses high-strength steel construction with hardened pins designed to withstand harsh environments.

Core Hardware Components

|

Component |

Function |

|---|---|

|

Mounting frame/plate |

Main structural element that attaches to the loader’s lift arms |

|

Upper hooks |

Catch and hold the top edge of attachment plates |

|

Lower locking wedges |

Clamp the bottom edge of attachments when engaged |

|

Pivot pins |

Allow lever and wedge movement during locking/unlocking |

|

Return springs |

Assist in lever and wedge return when unlocking |

|

Left/right control levers |

Operator interface for manual wedge engagement |

Model-Specific and Optional Parts

Depending on your loader model and configuration, you may also have:

- Hydraulic cylinders and hoses: For Power Bob-Tach systems

- Wear bushings: Replaceable components at high-friction pivot points

- Pivot kits: Complete sets for rebuilding worn pivot assemblies

- Hardware kits: Bolts, nuts, and fasteners for lever kit installation

The robust construction of these components contributes to the system’s reputation for durability, though regular inspection remains essential to maintain safe operation.

Bob-Tach Attachments and Typical Applications

The biggest advantage of Bob-Tach is the wide range of compatible work tools using the same interface. This versatility transforms a single loader into multiple machines, maximizing your equipment investment.

Core Earthmoving Tools

General-purpose buckets remain the most common Bob-Tach attachment, but the category expands significantly:

- General-purpose buckets: Standard digging and loading operations

- 4-in-1 buckets: Combine bucket, dozer, clam, and grading functions

- Grapple buckets: Secure grip on irregular materials like brush and debris

- Tooth buckets: Aggressive digging in compacted soils

Excavation-Focused Attachments

Bob-Tach backhoe units, trenchers, and augers plug into the loader’s auxiliary hydraulics for power, turning your skid steer into a compact excavation solution:

- Backhoes: Available in 13-inch, 16-inch, and 20-inch bucket sizes with 48-degree dipper swing

- Trenchers: Precision cutting for utility installation

- Augers: Post hole and foundation pier drilling

Winter and Grounds Maintenance

Seasonal attachments swap on and off using the same Bob-Tach plate:

- Snow blowers: For heavy accumulation

- Snow blades: For plowing

- Brooms: For sweeping and light snow removal

- Landscape rakes: For grounds preparation

Most modern Bobcat-branded attachments for loaders built from the early 2000s onward are designed around the Bob-Tach interface for plug-and-play fit. When you search for new attachments, verify the item ships with Bob-Tach compatibility or review the product details to confirm.

|

Attachment Type |

Typical Applications |

|---|---|

|

Grapple bucket |

Brush clearing, demolition debris, log handling |

|

Trencher |

Utility installation, irrigation lines, drainage |

|

Auger |

Fence posts, sign installation, tree planting |

|

Snow blade |

Parking lots, driveways, sidewalks |

|

Pallet forks |

Material handling, loading/unloading |

Compatibility With Skid-Steer and Compact Track Loaders

Many Bobcat skid-steer and compact track loader models share the Bob-Tach interface, simplifying fleet attachment sharing and reducing the number of specialized tools needed on job sites.

Compatible Skid-Steer Models

Representative Bobcat skid-steer models that commonly use Bob-Tach include:

- 751, 753, 763, 773 series

- 863, 873 series

- S100, S130, S150, S160 series

- A220, A300 all-wheel steer models

- Newer M2-series on 600 and 700 platforms

Compatible Compact Track Loader Models

Typical compact track loader models using the same interface:

- T110, T140 series

- T180, T190, T200 series

- T250 and similar generations

Important Compatibility Notes

While the Bob-Tach quick-attach pattern is widely standardized, operators must still confirm fitment in the loader’s manual, especially on older or very new series machines. The physical mounting pattern may match, but consider these factors:

- Hydraulic flow requirements: Some attachments need high-flow or super-flow auxiliary hydraulics

- Electrical connections: Certain tools require additional wiring for controls or sensors

- Rated operating capacity: Attachment weight affects your loader’s lifting capabilities

- Filters and settings: Auxiliary hydraulic flow settings may need adjustment

When you view product details for any attachment, check the stock specifications against your machine’s capabilities before adding to your cart.

Bob-Tach Backhoe Attachments and Hydraulics

Backhoe attachments are among the most popular Bob-Tach tools because they transform loaders into compact digging machines without requiring a separate excavator on site.

Mounting and Connection Process

The mounting process follows the standard Bob-Tach procedure with additional hydraulic connections:

- Approach and engage the backhoe’s Bob-Tach plate

- Lock the wedges using levers or Power Bob-Tach

- Connect hydraulic quick couplers from the loader’s auxiliary circuit

- Test all boom, dipper, and swing functions before starting work

Hydraulic Operation

The loader’s auxiliary hydraulics power all backhoe functions:

- Boom cylinder: Raises and lowers the digging arm

- Dipper cylinder: Controls the digging motion

- Bucket cylinder: Curls the bucket for digging and dumping

- Swing mechanism: Rotates the dipper 48 degrees left or right for spoil placement

Most Bob-Tach backhoes for Bobcat loaders do not require additional chassis-mounted kits or stabilizers, though operators must verify their machine meets the hydraulic flow and pressure requirements specified in the attachment’s documentation.

Ideal Applications

Bob-Tach backhoe attachments excel in situations where a dedicated excavator would be overkill or inaccessible:

- Trenching: For utilities and irrigation

- Small foundations and footings

- Drainage ditches and culvert installation

- Farm water lines and fencing

- Landscaping excavation in confined spaces

Bob-Tach Lever Kits and Replacement Parts

Lever kits are common wear-and-tear service items that restore positive locking action when original levers or wedges become loose, bent, or worn. For operators who have purchased used equipment or run machines in demanding conditions, understanding these parts is essential.

What's Included in a Lever Kit

A typical left and right hand control lever kit includes:

- Replacement levers (left and right)

- Linkage hardware and pivot pins

- Locking wedges or wedge pins

- Bushings for pivot points

- Return springs

- Mounting bolts and fasteners

When you search for parts, you’ll find kit variations by model. Common OEM-equivalent part numbers include 6724775 and 6724776 for certain Bobcat 743 loaders, though you should always verify the correct part number for your specific machine before making a verified purchase.

Signs Your Lever Kit Needs Replacement

Watch for these indicators that it’s time to add a new lever kit to your cart:

- Difficult lever movement: Excessive force required to lock or unlock

- Attachment play: Rattling or rocking that wasn’t present before

- Visible wear: Worn edges on wedges or elongated pin holes

- Incomplete travel: Levers won’t fully lock down

- Spring failure: Levers don’t return properly when released

Basic Replacement Procedure

While specific steps vary by model, the general process includes:

- Park on level ground with the loader’s attachment lowered or removed

- Turn off the engine and engage all safety locks

- Support the Bob-Tach plate to prevent movement

- Remove pins and hardware securing old levers

- Extract worn levers, bushings, and springs

- Install new kit components in reverse order

- Test lever operation before returning to service

Consult your loader’s service manual for detailed procedures specific to your machine. If this is your first time doing this work, consider having a dealer technician complete the job.

Maintenance, Safety, and Troubleshooting Tips

Regular Bob-Tach inspection is essential to prevent accidental attachment release and to keep coupling smooth and easy throughout your machine’s service life.

Routine Inspection Checklist

Incorporate these checks into your routine:

- Clean mounting surfaces: Remove mud, debris, and ice from both the Bob-Tach plate and attachments

- Check wedge travel: Verify wedges extend and retract fully

- Lubricate pivot points: Apply grease to reduce friction and prevent corrosion

- Inspect for damage: Look for cracks, bends, or distortion in the plate and hooks

- Test lever action: Confirm smooth operation without excessive play

Critical Safety Reminders

- Always lower attachments to the ground before working on the Bob-Tach system

- Follow your loader’s operator manual procedures

- Never stand under a raised attachment

- Verify full engagement before lifting or operating any attachments

Common Bob-Tach Problems and Solutions

|

Problem |

Possible Causes |

Solutions |

|---|---|---|

|

Levers hard to move |

Rust, bent pins, debris buildup |

Clean, lubricate, or replace worn components |

|

Attachment won’t seat fully |

Debris in hooks, damaged plate |

Clean thoroughly, inspect for damage |

|

Power Bob-Tach won’t move |

Hydraulic issue, valve problem |

Check hoses, fluid level, and valve function |

|

Attachment rocks or rattles |

Worn wedges, loose hardware |

Inspect and replace lever kit if needed |

Documentation Recommendations

For commercial fleets, maintain a log of:

- Inspection dates and findings

- Parts replaced with part numbers and cost

- Operating hours at time of service

- Any recurring issues by machine

This documentation helps you find wear patterns and plan maintenance more effectively, reducing unexpected downtime and improving overall fleet security.

FAQ

This section answers common questions operators and buyers have about Bob-Tach systems, attachments, and lever kits beyond what was covered in the main article.

Q1: Can I retrofit a Bob-Tach mounting system onto an older loader?

A1: Many older Bobcat and non-Bobcat loaders can be upgraded with adapter plates or weld-on mounts designed to match the Bob-Tach pattern, but fitment must be verified case-by-case. Retrofits should be performed by qualified fabricators or service centers to maintain structural integrity and safe attachment locking. Consult both the loader manufacturer and the adapter supplier for load limits and warranty implications before modifying the machine. The price of a good retrofit varies significantly depending on the tractor or loader model and the extent of modifications required.

Q2: Will a Bob-Tach attachment fit non-Bobcat machines?

A2: Many brands now support a “Bob-Tach style” or compatible quick-attach interface, so numerous non-Bobcat loaders can accept Bob-Tach pattern attachments via compatible front plates. This category of compatibility has expanded significantly as the interface became an industry standard. However, even if the physical pattern is a match, hydraulic flow, electrical connectors, and rated lift capacities may differ. Always confirm compatibility in your loader’s manual or with the dealer before using heavy or high-flow Bob-Tach attachments.

Q3: How often should I inspect my Bob-Tach lever kit and wedges?

A3: A quick visual and functional check should be done daily or before each shift—verify full lever travel and that wedges fully engage and release. Set a plan for more detailed inspection at least every 250 operating hours or during scheduled loader service. Operations in abrasive or corrosive environments (road salt, demolition, wet clay) may require more frequent inspections. Some fleet managers review their equipment monthly from January through Feb during heavy snow removal season due to increased salt exposure.

Q4: Do I need special tools to replace a Bob-Tach control lever kit?

A4: Most lever kits can be installed with standard workshop tools such as sockets, wrenches, punches, and pliers, along with penetrating oil for seized pins. The good news is that specialized equipment typically isn’t required. The loader must be parked on level ground with the engine off and attachments fully lowered or removed before any disassembly begins. First-time installers should follow the detailed procedure in the loader’s service manual or choose to have a dealer technician complete the job.

Q5: What are signs that my Bob-Tach system is unsafe to use?

A5: Warning signs that indicate immediate attention is needed include:

- Visible cracking or bending of the mounting plate

- Levers that will not stay locked down

- Attachments that rock excessively when lifted

- Wedges that will not fully extend

- Broken or missing springs or bolt hardware

If any of these conditions appear, take the loader out of service until the Bob-Tach is repaired or components replaced. In fleet environments, encourage operators to report issues immediately so supervisors can schedule inspection before further use—addressing a problem early prevents more costly repairs and potential safety incidents.

Recommended Replacement Parts for Bobcat at Fab Heavy Parts

1.

Shop Fuel Injectors for Bobcat

Shop Fuel Injectors for Bobcat

2.

3.

Shop Air Conditioning Compressors for Bobcat

Shop Air Conditioning Compressors for Bobcat

4.

Shop Starter Motors for Bobcat

Shop Starter Motors for Bobcat

5.

FAB Heavy Parts: Your Trusted Engine Parts Supplier

Welcome to Fab Heavy Parts' online catalog, your trusted source for quality auto parts and tools. Explore our extensive selection of replacement parts for Bobcat and more. Avoid delays by securing the parts you need from a reliable supplier who keeps inventory moving. Our expert team is here to provide personalized support, ensuring you get the right parts. Reach out today to stay ahead and keep your operations seamless!