Key Takeaways

- The Doosan D34 is a 3.4-liter, 4-cylinder inline diesel engine delivering 74–134 hp (55–100 kW), designed for compact industrial and off-highway equipment including loaders, telehandlers, and generator sets.

- Displacement is exactly 3,409 cm³ with a bore of 98 mm and stroke of 113 mm, featuring common-rail fuel injection and turbo-intercooled aspiration for strong low-end torque of up to 500 Nm at 1,400 rpm.

- The engine meets Tier 4 Final and EU Stage V emissions standards through DOC, DPF, and optional SCR after-treatment, with newer variants eliminating EGR for improved reliability and reduced maintenance effort.

- Typical applications include Bobcat skid steers, track loaders, all-wheel steer loaders, versahandlers, and various generator sets in the 55–100 kW power band.

- Fab Heavy Parts supplies replacement and OEM-equivalent parts, overhaul kits, and technical assistance for Doosan D34 engines to support maintenance, repair, and rebuild projects worldwide.

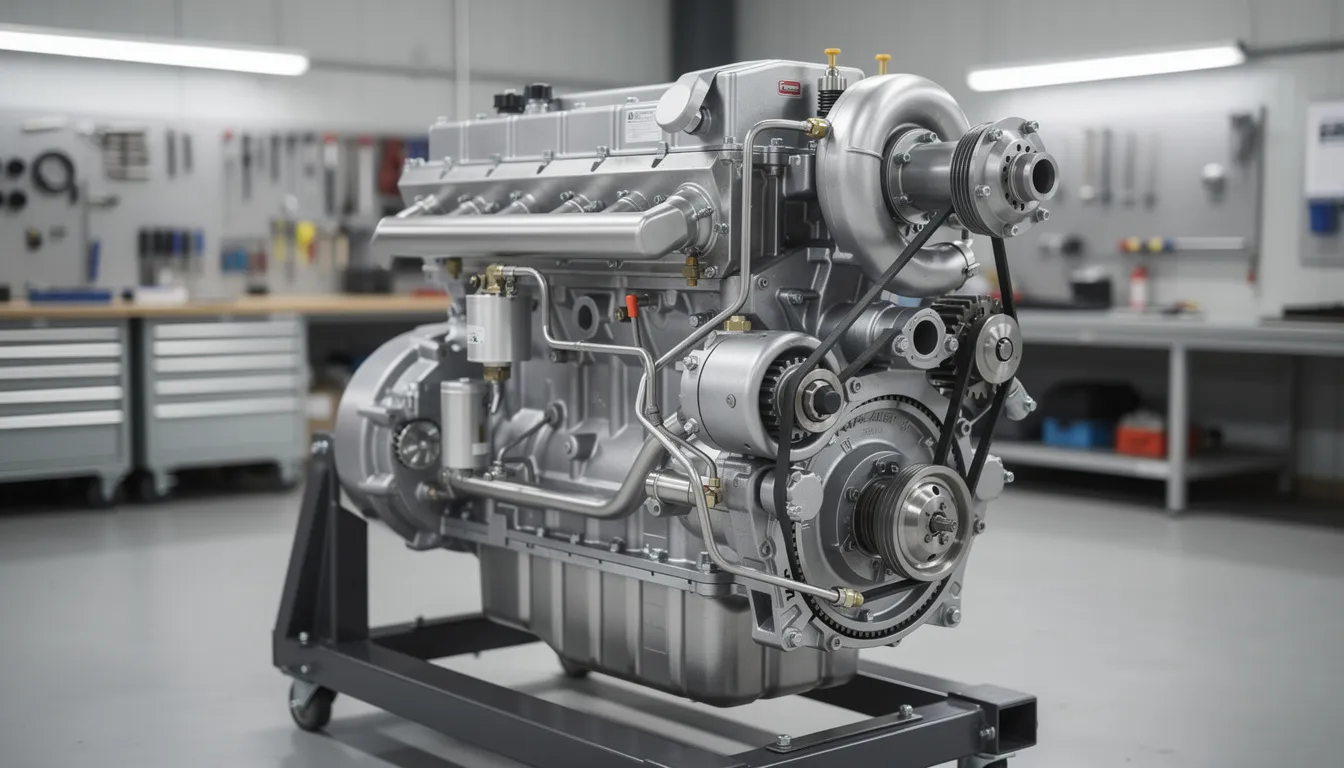

Introduction to the Doosan D34 Engine

The Doosan D34 engine represents a purpose-built industrial diesel designed to power compact construction and material-handling equipment. Introduced around 2012-2013 for Korean compact machine applications and evolved through multiple emission stages, this 3.4-liter inline four-cylinder has become a workhorse in the 55–100 kW power category. Its robust construction and modern emissions technology make it suitable for demanding off-highway operation where reliability and fuel efficiency matter.

You’ll find the D34 powering a range of equipment including skid steer loaders, track loaders, all-wheel steer loaders, telehandlers, and generator sets. The engine’s design emphasizes strong low-rpm torque for heavy lifting and maneuvering cycles, combined with the documentation and service support that fleet managers require. Understanding the technical data for this platform helps owners and technicians choose correct components, plan maintenance schedules, and evaluate engine upgrades or replacements. From our perspective at fabheavyparts.com, accurate specifications form the foundation of successful parts sourcing and repair planning.

Core Technical Specifications

This section summarizes the main technical data covering configuration, displacement, ratings, and basic performance numbers that define the Doosan D34 engine platform.

Engine Configuration

The D34 uses a 4-cylinder inline layout operating on a 4-stroke diesel cycle. It features turbocharged aspiration with air-to-air intercooling and a high-pressure common-rail fuel injection system supplied by DELPHI DFP 4.2 pumps. The engine employs direct injection combustion in a linerless cylinder design, with overhead valves arranged as 2 intake and 2 exhaust per cylinder. The firing order follows a 1-3-4-2 sequence with counterclockwise rotation when viewed from the flywheel.

Displacement and Geometry

|

Parameter |

Specification |

|---|---|

|

Displacement |

3,409 cm³ (3.4 L) |

|

Bore |

98 mm |

|

Stroke |

113 mm |

|

Compression Ratio |

17.0:1 to 18.0:1 |

|

Cylinders |

4 inline |

The compression ratio varies depending on the emissions variant and calibration, with higher ratios supporting improved fuel economy in certain configurations.

Power and Performance

Power ratings adapt to specific applications and emissions compliance requirements:

- Intermittent ratings: 128.7 hp (96.0 kW) at 2,400 rpm or 134.0 hp (100.0 kW) at 2,800 rpm in non-DPF Tier 4 configurations

- Continuous ratings: 115.8 hp (86.4 kW) to 120.0 hp (90.0 kW) for sustained operation

- Generator applications: 55.4 kWm gross output at 1,500 or 1,800 rpm governed speeds under Stage V compliance

- Compact T4F models: 110 hp (55 kW) maximum at 2,400 rpm

Peak torque reaches 368.8 ft-lbs (500 Nm) at 1,400 rpm, providing the low-end pulling power essential for heavy-duty construction cycles. This torque characteristic means operators experience responsive performance during digging, lifting, and pushing operations without needing to run at high rpm.

Fuel and Lubrication Systems

The D34 requires ultra-low sulfur diesel (ULSD) with a maximum sulfur content of 15 ppm. The fuel system includes multi-hole injection nozzles and full-flow cartridge filters. Fuel inlet pressure operates within 0.5–1.5 bar, with return pressure at 1.2 bar.

Lubrication relies on a fully forced pressure feed system with minimum idle oil pressure of 100 kPa. The engine uses spin-on filters for straightforward service access.

Cooling and Starting

The liquid-cooled system holds 4.7 liters of engine coolant (12.1 liters when including the powerpack), with pressure caps rated at 0.9 bar. Starting options include 12V or 24V electric starters depending on OEM machine specifications, with air heaters or glow plugs available as cold-start aids.

Dimensions, Weight & Installatin Envelope

Understanding the physical footprint of the Doosan D34 engine helps equipment engineers and rebuilders plan installations, lifting requirements, and machine balance considerations during replacement or repowering projects.

Overall Dimensions

|

Dimension |

Specification |

|---|---|

|

Length |

889.6–896.9 mm |

|

Width |

655.2 mm |

|

Height |

804.5–992 mm (depending on after-treatment) |

Height variations primarily result from different after-treatment configurations. DOC-only setups measure approximately 804.5 mm, while DOC+DPF+SCR packages can extend to 992 mm. Optional cooling fans add approximately 475 mm to the overall envelope.

Weight Specifications

Dry weight varies by configuration:

- Bare engine excluding flywheel housing: 335 kg

- Engine without mounting brackets: 493 kg

- Fully equipped industrial configuration: approximately 500 kg

These weights impact transport logistics, lifting equipment selection, and machine balance calculations when replacing engines or designing new installations.

Mounting and Interface Details

The D34 features a conventional inline-4 block design with side engine mounts. Flywheel housings conform to SAE #3 (11.5”) or SAE #4 (10”) standards, with 125-tooth flywheels supporting various transmission and pump drive arrangements. Battery requirements specify minimum 100 Ah capacity with 950 CCA for reliable starting.

Installation clearances must accommodate the turbocharger assembly, after-treatment components (DOC/DPF/SCR), and cooling package. While OEM machines may package these differently, the base engine dimensions remain consistent across applications. Air flow requirements reach up to 7,680 liters/min at full load.

Fab Heavy Parts can assist customers in confirming compatibility when repowering older equipment or sourcing replacement long blocks and short blocks for the D34 platform.

Emission Standards & After-Treatment Technology

The Doosan D34 was engineered to meet modern emissions regimes including U.S. EPA Tier 4 Final and EU Stage V, with different hardware configurations depending on model year and target market. Understanding these systems helps operators maintain compliance while managing service requirements.

Emission Control Hardware

Typical D34 variants employ a tiered approach to emission control:

- Diesel Oxidation Catalyst (DOC): Reduces carbon monoxide and hydrocarbons through catalytic oxidation

- Diesel Particulate Filter (DPF): Captures soot particles for periodic regeneration

- Selective Catalytic Reduction (SCR): Uses diesel exhaust fluid (DEF/AdBlue) to convert NOx into nitrogen and water

Some industrial variants achieve Tier 4 Final compliance using DOC-only after-treatment, eliminating DPF maintenance requirements for applications where this configuration meets regulatory standards.

No-SCR and No-EGR Configurations

A significant development in later D34 variants involves eliminating both EGR valves and SCR systems. These No-SCR Stage V options rely on optimized combustion, DOC+DPF after-treatment, and precise ECU calibration to meet emission standards without the complexity of urea injection systems. Benefits include:

- Reduced maintenance effort and component count

- Elimination of DEF consumption and storage requirements

- Improved reliability in harsh operating environments

- 500-hour service intervals versus shorter intervals on EGR/SCR systems

DPF Regeneration Strategy

The DPF regeneration process operates through both passive and active modes:

Passive regeneration occurs naturally during normal operation when exhaust temperatures remain high enough to oxidize accumulated soot. This typically happens during sustained loading at 1,500–1,800 rpm.

Active regeneration initiates when the ECU detects excessive soot loading. The system injects additional fuel to raise exhaust temperatures, burning off accumulated particles. Operators may notice slightly elevated fuel consumption during active regeneration cycles.

Correct engine loading and fuel quality directly affect soot accumulation rates. Light-load operation that prevents passive regeneration can accelerate DPF clogging, while poor fuel quality may introduce contaminants that complicate regeneration.

DEF Consumption and Planning

For SCR-equipped D34 variants, DEF consumption typically runs 2–6% of fuel use depending on duty cycle intensity. Fleet operations should plan for DEF supply logistics alongside fuel delivery, with particular attention to winterization procedures that prevent DEF freezing in cold weather.

Fab Heavy Parts supports customers with compatible sensors, NOx modules, temperature probes, and other emissions-related components for the D34 platform.

Applications & Machine Compatibility

The Doosan D34 engine serves as the power source for numerous compact and mid-size construction machines rather than functioning as a standalone product. Understanding typical applications helps owners identify correct parts and service specifications.

Primary Equipment Types

The D34 powers a wide range of equipment categories:

- Skid steer loaders: Including Bobcat S740, S750, S770, and S850 series

- Track loaders: Bobcat T740, T750, T770, and T870 compact track loaders

- All-wheel steer loaders: Bobcat A770 and similar maneuverable loader designs

- Versahandlers: Bobcat V519 and V723 telehandler models

- Generator sets: Industrial gensets in the 60 kVA class for standby and prime power applications

- Air compressors: Mobile compressor units for construction and industrial use

Operating Weight Classes

Machines using the D34 typically fall within the compact to mid-size operating weight range where the engine’s 100 kW power band and 500 Nm torque output provide appropriate performance. The strong low-rpm torque characteristic at 1,400 rpm excels in applications requiring heavy lifting, pushing, and maneuvering without the need to maintain high engine speeds.

OEM and Industrial Applications

Beyond Bobcat and Doosan/Develon branded equipment, OEMs outside these brands may specify D34 industrial engines for specialized machinery, pumps, and off-highway applications. The engine’s Stage V compliance and No-SCR options make it attractive for equipment manufacturers seeking simplified emission systems.

Parts Identification Requirements

Understanding the exact D34 variant is essential when sourcing compatible parts. Key identification information includes:

- Power rating and calibration

- Emission stage (Tier 4 Final, Stage V, etc.)

- ECU calibration code

- Engine serial number and arrangement number

Fab Heavy Parts can help decode engine serial numbers and plate data to ensure precise parts matching for your specific Doosan D34 variant.

Fuel System, Air System & Performance Characteristics

This section examines how the D34 delivers power efficiently through its integrated fuel and air management systems, directly related to the engine’s productivity in demanding applications.

High-Pressure Common-Rail Injection

The D34 uses DELPHI DFP 4.2 high-pressure pumps feeding a common-rail injection system. Key characteristics include:

- Multiple injection events per combustion cycle to reduce noise and emissions

- Multi-hole nozzles for precise fuel atomization

- ECU-controlled injection timing and quantity for optimized performance across the operating range

- Full-flow cartridge fuel filters requiring ultra-low sulfur diesel

The electronic control program manages injection parameters based on load, speed, and temperature inputs, automatically adjusting for varying operating conditions.

Turbocharging and Intercooling

The turbocharged, air-to-air intercooled aspiration system increases air density, allowing higher specific power from the 3.4-liter displacement. This configuration supports:

- Improved volumetric efficiency at all operating speeds

- Reduced intake air temperatures for denser charge air

- Enhanced altitude performance compared to naturally aspirated alternatives

- Maximum air flow of 7,680 liters/min at peak operation

Maximum exhaust temperatures remain controlled below 750°C at 2,600 rpm, protecting turbocharger and after-treatment components from thermal damage.

Power and Torque Curves

The D34’s performance characteristics emphasize strong low-rpm torque for construction applications:

|

Operating Point |

Value |

|---|---|

|

Peak Torque |

500 Nm at 1,400 rpm |

|

Maximum Power |

Up to 134 hp at 2,800 rpm |

|

Idle Speed |

800 rpm |

|

Rated Speed Range |

2,200–2,800 rpm depending on calibration |

The relatively flat torque plateau between 1,400–1,800 rpm means operators experience consistent pulling power during variable loading cycles without excessive gear shifting or rpm hunting.

Fuel Consumption

Specific fuel consumption varies by duty cycle and power setting:

- Generator applications show consumption as low as 4.2 liters/hour at 25% load

- Full-load operation increases consumption proportionally

- Brake mean effective pressure operates in the 1.6–1.8 MPa range during steady-state generator duty

Real-world fuel burn depends heavily on machine hydraulic demands, operator technique, and site conditions. The mathematical relationship between fuel consumption and power output follows typical industrial diesel patterns, with part-load efficiency benefiting from the common-rail system’s precise fuel metering.

fabheavyparts.com can supply key fuel-system components such as injectors, fuel rails, high-pressure pumps, filters, and turbocharger units to restore D34 performance during overhaul or repair projects.

Maintenance, Service Intervals & Reliability

Correct maintenance is vital to leveraging the D34’s design life, especially under demanding off-highway conditions where dust, vibration, and thermal cycling challenge every system.

Standard Service Intervals

Doosan publishes the following typical service intervals for normal operating conditions:

|

Service Item |

Interval |

|---|---|

|

Engine oil and filter change |

500 hours |

|

Fuel filter replacement |

500 hours |

|

Air filter inspection/replacement |

500 hours (or as condition requires) |

|

Coolant service |

Per OEM schedule |

|

Valve clearance check |

Not required (hydraulic lash adjusters) |

Severe-service environments involving high dust, extreme temperatures, or continuous heavy loading may require shortened intervals. The hydraulic valve lash adjusters eliminate periodic valve adjustment, reducing maintenance effort compared to engines requiring manual clearance checks.

Emissions System Maintenance

Emissions-related maintenance includes information on:

- DPF cleaning or exchange: Based on soot loading and ash accumulation over time

- Sensor inspections: NOx sensors, temperature probes, and pressure differential sensors

- DEF system winterization: Preventing freezing and ensuring proper dosing function

- Software updates: Via dealer diagnostic tools for ECU calibration refinements

The No-SCR, no-DPF industrial variants significantly reduce emissions system maintenance requirements, offering 500-hour intervals versus shorter schedules on EGR/SCR-equipped systems.

Reliability Characteristics

Design strengths of the D34 platform include:

- Robust block and cylinder head castings in linerless configuration

- Durable bottom-end construction with proven bearing systems

- Mature common-rail technology with extensive field validation

- Maintenance-free hydraulic valve lash adjusters

Common wear items to monitor include injectors, EGR valves (on certain variants), turbocharger bearings, and after-treatment components. Regular oil analysis provides early warning of internal wear trends.

Parts Support for Planned Maintenance

Fab Heavy Parts offers maintenance kits including oil filters, fuel filters, air filters, seals, and gaskets specifically tailored for Doosan D34 engines. These kits simplify planned services and support in-frame rebuild projects by ensuring all required components are available in a single order.

Doosna D34 Parts, Rebuild Options & Support from Fab Heavy Parts

Fabheavyparts.com serves as a specialized supplier of heavy equipment engine parts, with extensive coverage for the Doosan D34 platform. Whether you need individual components for targeted repair or complete assemblies for major overhaul, our category of products supports your maintenance and production requirements.

Available Component Categories

We provide D34 components across major system areas:

Engine Core Components

- Complete long blocks and short blocks

- Cylinder heads (bare and assembled)

- Gasket sets for overhaul and in-frame rebuilds

- Pistons, liners (where applicable), and ring sets

- Bearings (main, rod, camshaft)

- Crankshafts and camshafts

- Oil pumps and water pumps

Fuel and Air System Parts

- Injectors (new and remanufactured)

- Common-rail assemblies

- High-pressure fuel pumps

- Turbocharger units

- Fuel filters and filter housings

- Air intake components

Emission System Components

- DOC and DPF assemblies

- SCR catalyst units

- Sensors (NOx, temperature, pressure)

- DEF lines and dosing components

- After-treatment mounting hardware

FAQ

These frequently asked questions address practical concerns not fully covered in the sections above, providing additional instructions and information for D34 owners and service providers.

Q1: What is the typical service life of a Doosan D34 engine in construction equipment?

A1: With proper maintenance and correct loading, many D34 engines exceed 8,000–12,000 operating hours before requiring major overhaul. Actual life depends heavily on operating environment, service discipline, fuel quality, and operator behavior. Regular oil analysis, consistent filter changes, and monitoring of coolant condition and intake cleanliness are key to reaching higher hour counts. Engines operating in severe conditions with high dust loading or frequent thermal cycling may require earlier attention to wear items. fabheavyparts.com can supply complete overhaul kits when machines approach end-of-life for critical components, supporting either in-frame rebuilds or complete engine assembly replacement.

Q2: How do I identify the exact Doosan D34 variant installed in my machine?

A2: Locate the engine identification plate or stamped number on the block, which typically includes model code, serial number, and sometimes specification or emission code. Cross-check this data against the machine’s build plate or owner’s manual to confirm power rating and emission stage. The definition of variant often depends on calibration and after-treatment configuration rather than obvious physical differences. Customers can send plate photographs to fabheavyparts.com so our team can confirm correct parts and technical data for their specific D34 variant, ensuring accurate modification or replacement component selection.

Q3: Can the Doosan D34 be repowered into older machines that used different engines?

A3: Repowering is technically possible but requires careful assessment of mounting points, bellhousing compatibility, flywheel specifications, cooling capacity, exhaust routing, and after-treatment packaging. Emissions compliance and certification may be a factor when installing a modern Tier 4 Final or Stage V engine into older equipment, as regulatory requirements vary by jurisdiction. The production and development of successful repower projects typically involves collaboration between experienced installers and parts suppliers. Interested owners should consult with qualified technicians and share detailed machine data with fabheavyparts.com to discuss parts, adapters, and potential challenges before committing to the work.

Q4: What fuel and oil quality does the Doosan D34 require?

A4: D34 engines are designed for ultra-low sulfur diesel (ULSD) meeting EN 590 or ASTM D975 specifications, with sulfur content limited to 15 ppm maximum. Bio-diesel blends should remain within Doosan’s approved percentage limits as documented in official service manuals. Engine oil must meet the viscosity and performance category specified by Doosan, typically API CK-4 or equivalent, with viscosity selection adjusted for ambient temperature conditions. Poor-quality fuel or oil can accelerate injector wear, create DPF issues, and cause internal engine damage that undermines expected service life. Proper testing and sampling programs help ensure fuel delivered to your site meets required specifications.

Shop Replacement Parts Fit for Doosan D34 Engine

FAB Heavy Parts: Your Trusted Engine Parts Supplier

Welcome to Fab Heavy Parts' online catalog, your trusted source for quality auto parts and tools. Explore our extensive selection of replacement parts for Doosan D34 Engine and more. Avoid delays by securing the parts you need from a reliable supplier who keeps inventory moving. Our expert team is here to provide personalized support, ensuring you get the right parts. Reach out today to stay ahead and keep your operations seamless!